PRESTAIN COLOR

SUBSTRATES

- X-Bond Seamless Stone

- Unsealed Concrete

- Exposed concrete

- Concrete block, tilt-up

- CMU, masonry

- Vertical, horizontal and below grade surfaces

COVERAGE

sq ft / gallon, 2 coats

| Polished concrete | 250 – 300 |

| Stamped concrete | 250 – 300 |

| Green concrete | 200 – 300 |

| Below grade | 200 – 250 |

| X-Bond Seamless Stone | 250 – 300 |

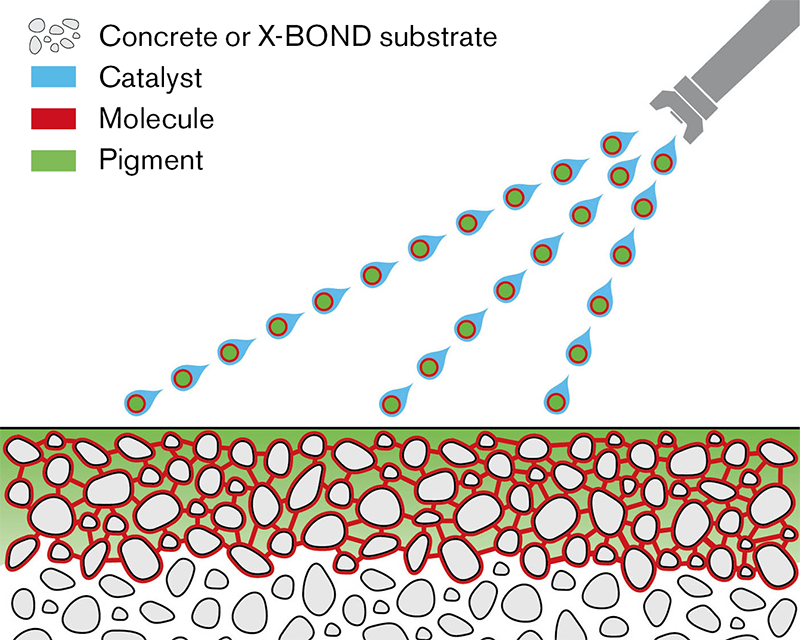

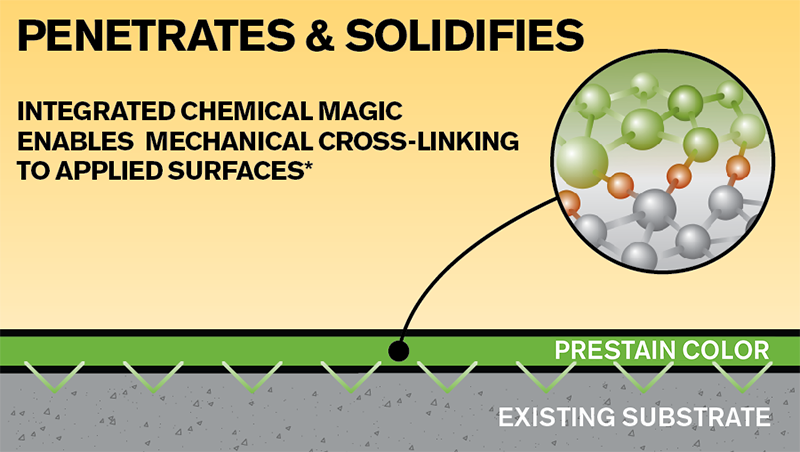

HOW PreStain Color WORKS?

PreStain Color penetrates deep into the pores of your cementitious surface to create a long lasting and colorful surface. In addition it solidifies crumbling surfaces. Unlike competitors SEMCO’s PreStain Color is proven to last through all kinds of climates, conditions and traffic.

* Drawing is not to scale

FEATURES AND BENEFITS OF PreStain Color

The SEMCO PreStain Color is a water-based, reactive/penetrating color system that provides rich, lasting color on exterior, interior and below grade concrete, masonry and X-Bond Seamless Stone surfaces. This environmentally responsible system creates lasting surface colors. Unique catalytic reactions provide natural, vivid, one-of-a-kind visual designs. Artistry and practicality combine to create beautiful and functional applications.

ACTIVE ADHESION

Integrated chemical adhesion enables mechanical cross-linking to applied surfaces, creating a perfect bond for long lasting protection.

* Drawing is not to scale

UV/fade resistance

PreStain Color has been specially formulated to produce a most durable UV/fade resistance. It will give your surface a long-lasting and vivid color making your surface one of a kind.

* Drawing is not to scale

Alkali resistance

PreStain Color is formulated to produce a durable alkali resistant surface.

* Drawing is not to scale

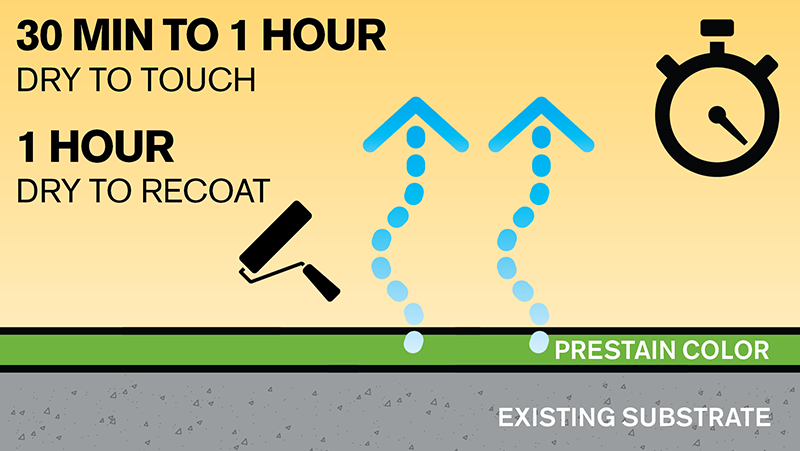

SHORT DRYING TIMES

With its fast drying properties, PreStain Color ensures a quick application time and allows your surface to be walked on within a matter of hours, getting your remodel done in less time.

* Drawing is not to scale

AVAILABLE COLORS

* Variations in color may occur depending on application, substrate condition and finishing sealer

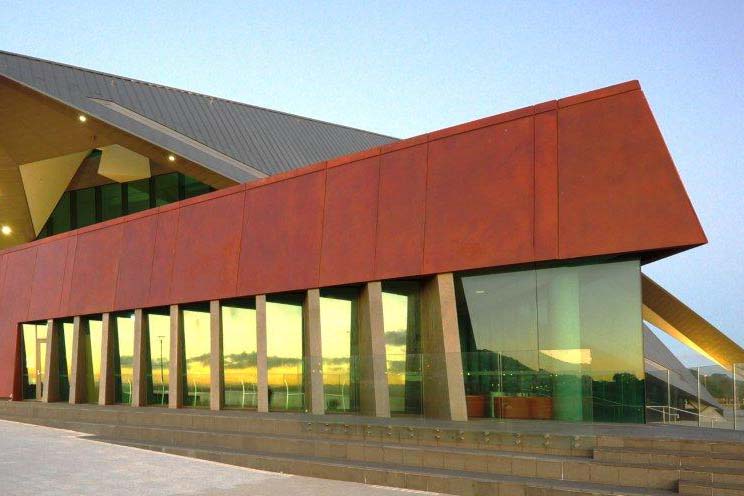

FEATURED PROJECTS

APPLICATION

Airless sprayer

tip size 15, 600 PSI

Pump sprayer

2 coats minimum

Roller

2 coats minimum

Apply at temperatures from 50°F to 90°F

Application instructions

STAGE 1 – PREPRATION OF SURFACE

- HOW : Lightly sand the surface with a 60 grit sanding disk. Clean all debris

PURPOSE : Removes excess texture and ensures chemical bond

STAGE 2 – APPLICATION OF NATURAL STAIN

- HOW : Using fine pump sprayer, spray light coat of PreStain Base on to surface and avoid large drops. Work in 2 man teams side by side(1 with Pump Sprayer and 1 with HVLP). For concrete surfaces spray thin coats with HVLP.

PURPOSE : Ensures chemical reaction of Natural Grain effect

- HOW : While still wet apply PreStain Color (PreStain Base and PreStain Activator combined, always stir the contents, avoid shaking) with an HVLP, airless sprayer with tip size 17, or a sprayer that is capable of atomizing liquids. (DO NOT ALLOW PUDDLING)

PURPOSE : Do not shake to avoid in container reaction. No puddles for even color, must spray with low pressure for a pigment reaction

- HOW : Move across area from left to right as you work your way down the surface, avoid missing any areas of the surface. Avoid stepping in Natural Stain

PURPOSE : Ensures the finish and color stay consistent

- HOW : The PreStain Color will then begin to dissipate and as the product forms to the contours of the X-Bond surface.

PURPOSE : Chemical reaction creates the Natural Grain look

- HOW : After drying, check if any area requires touch up. If necessary, lightly fog PreStain Color over areas that require touch up

PURPOSE : Ensures a nice finish

Scan QR Code to watch our application instruction step by step for a successful install or by clicking on this link !

SPECIFICATIONS

| Color | White/milky liquid |

| Chemical type | Water based reactive latex |

| Clean up | SEMCO Stone Soap with water |

| Shelf life | 1 year in controlled environment (ambient temperature of 60ºF – 72ºF) |

| Useful life | 5 years in controlled environment (ambient temperature of 60ºF – 72ºF) |

| Packaging | 1 gal. pail | 5 gal. pail | 55 gal. drum |

LABORATORY TEST RESULTS

| EN 13144 and ISO 4624 (pull-off) tests | Pass |

| UV resistance | Excellent |

| Surface penetration (4000 psi concrete, broom finish) | Up to 0.75 cm |

| Transmission fluid | Good |

| Water | Excellent |

| Alkali resistance | Good |

| Hydrolic acid (10%) | Good |