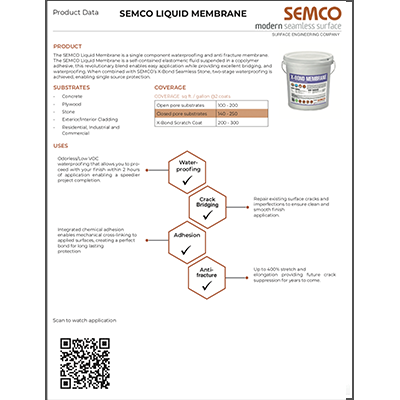

WHY SEMCO LIQUID MEMBRANE™?

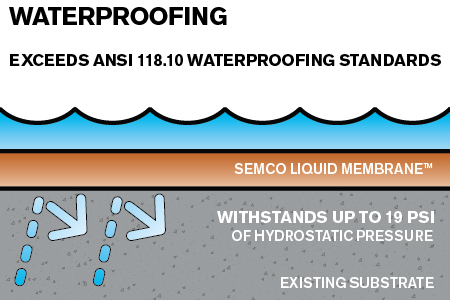

The SEMCO Liquid Membrane™ is a single component water-based waterproofing and anti-fracture membrane. It is a self-contained elastomeric fluid suspended in a copolymer adhesive, this revolutionary blend enables easy application while providing excellent bridging, and waterproofing.

COVERAGE

sq ft / gallon, 2 coats @ 15 mil per coat

| Open pore substrates | 100 – 150 |

| Closed pore substrates | 200 – 250 |

| X-Bond Scratch Coat | 150 – 200 |

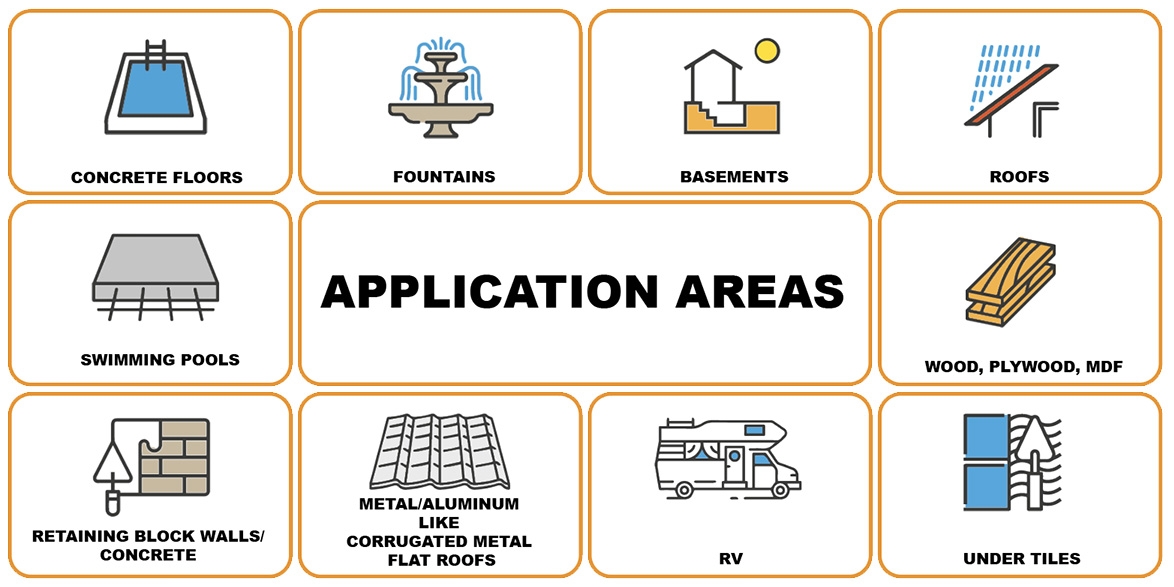

APPLICATION AREAS

Waterproof Everything, Adhere to Everything, SEMCO Liquid Membrane™ Everything

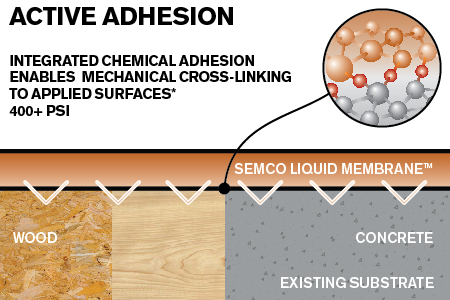

Integrated chemical adhesion enables mechanical cross-linking to the applied surfaces, creating a perfect bond for long lasting protection.

Low VOC waterproofing that allows you to proceed with your finish within 2 hours of application enabling a speedier project completion.

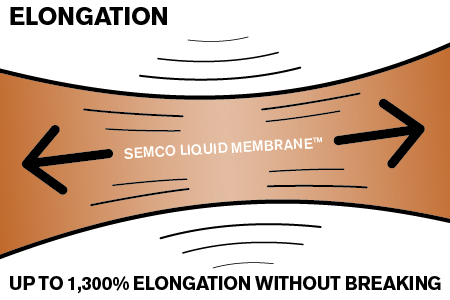

Up to 1,300% stretch and elongation providing future crack suppression for years to come. Stabilizes wood substrates to receive surface finish products.

FEATURED PROJECTS

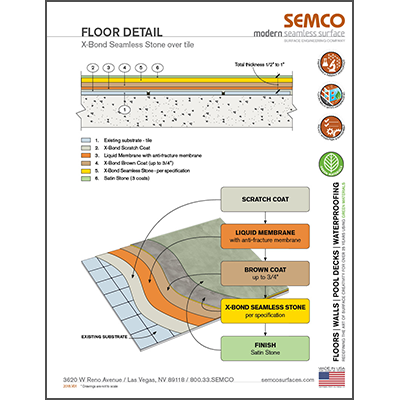

APPLICATION

Roller

1/2″ nap roller | 2 coats

Paint brush

2 coats minimum

Sprayer Application

0.521 reversible tip | 2 coats minimum

Apply at temperatures from 50°F to 90°F

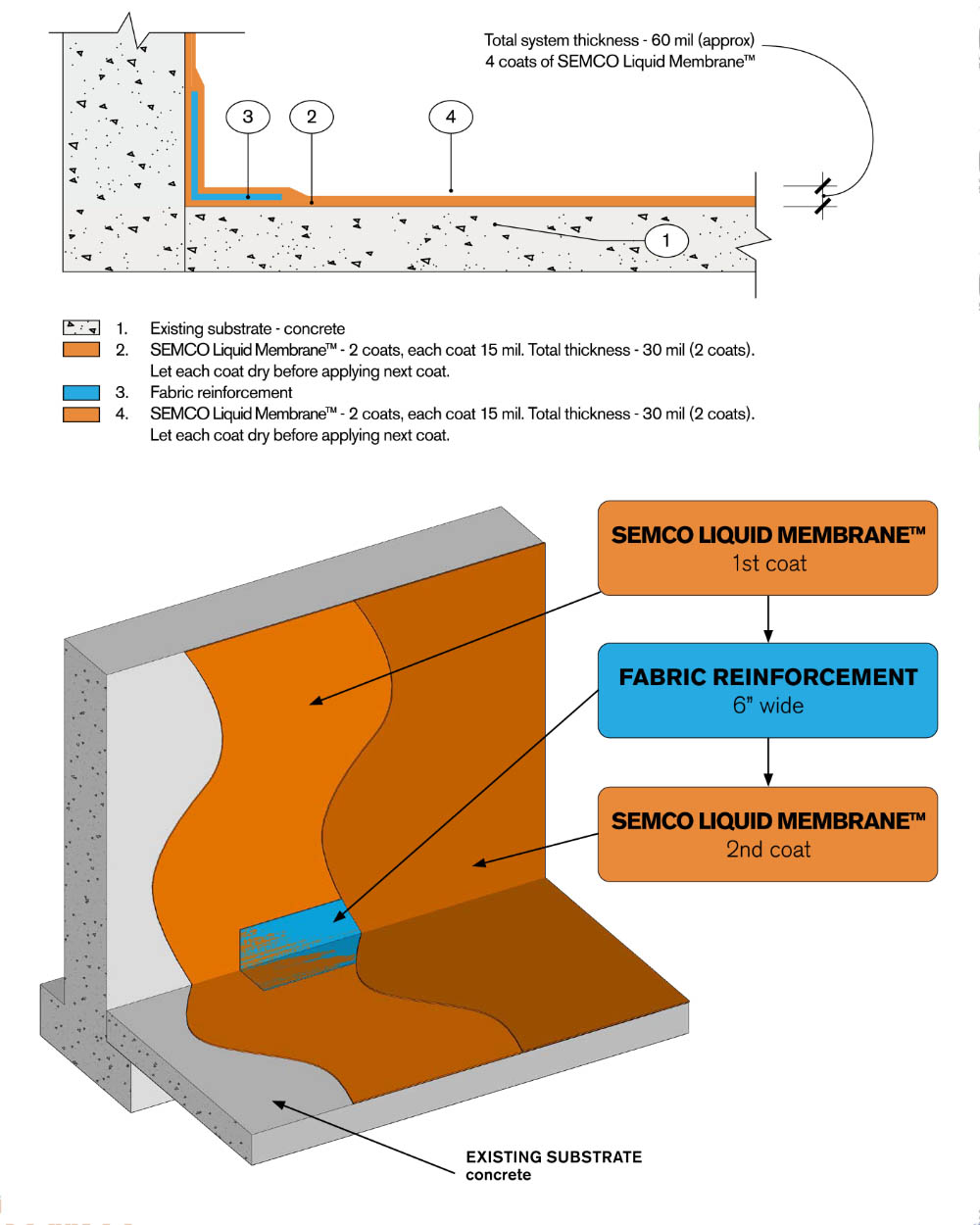

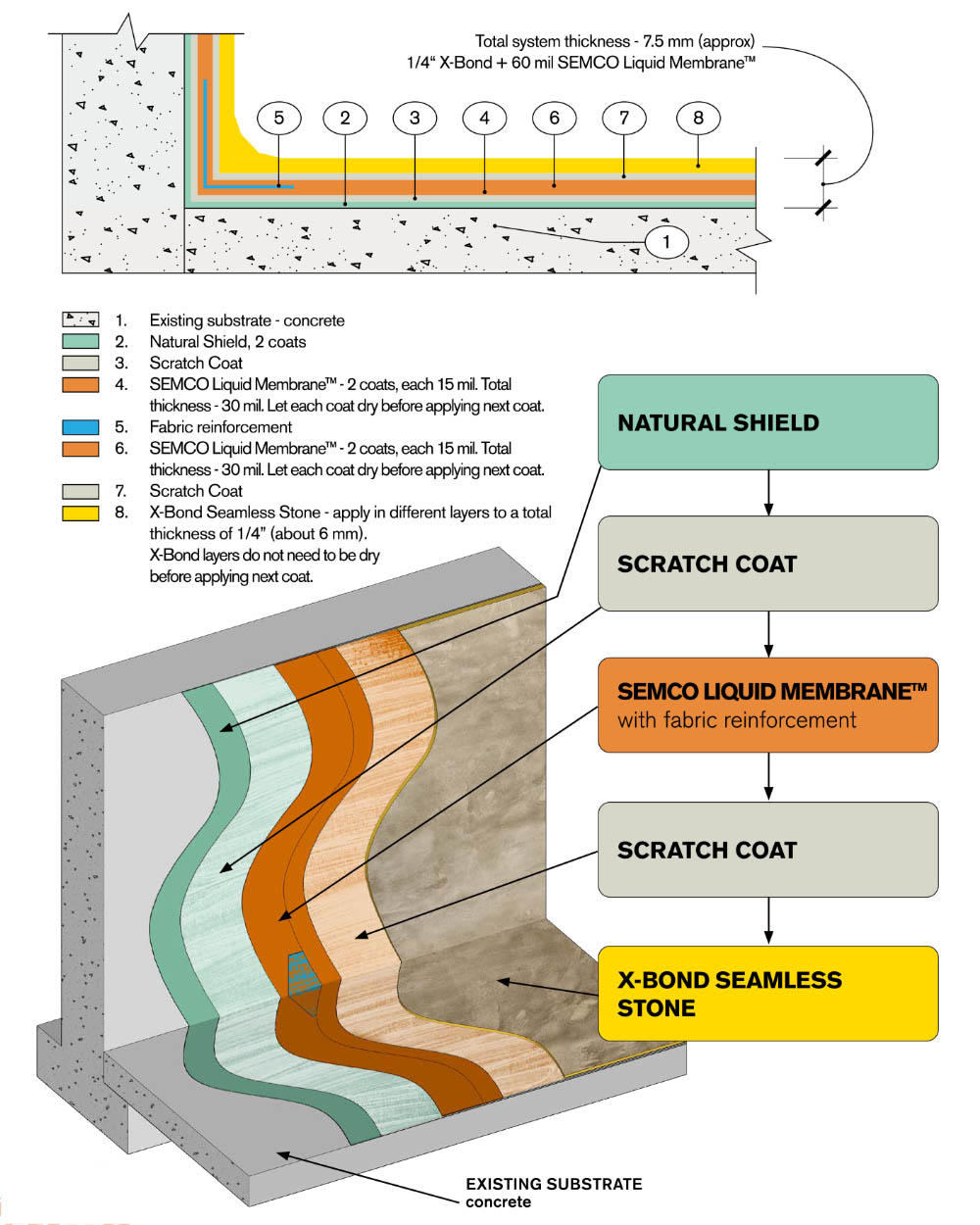

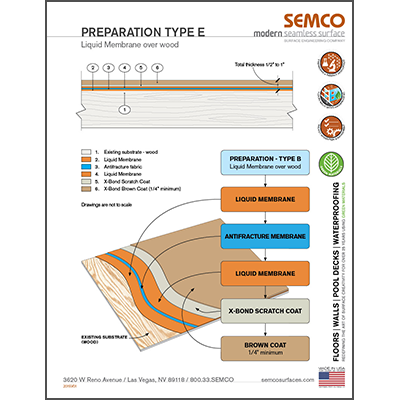

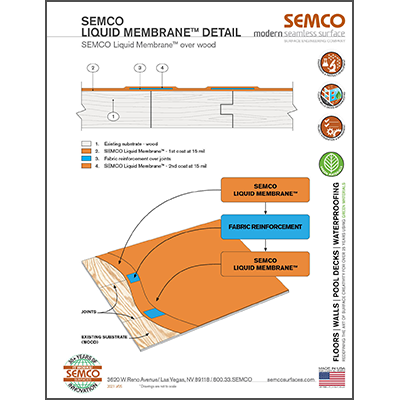

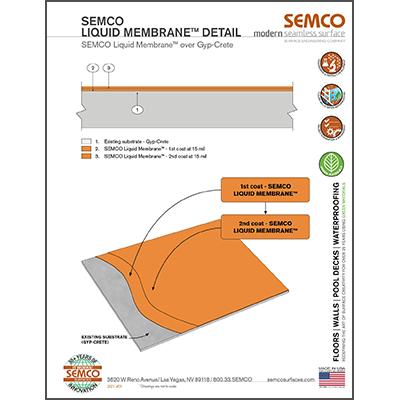

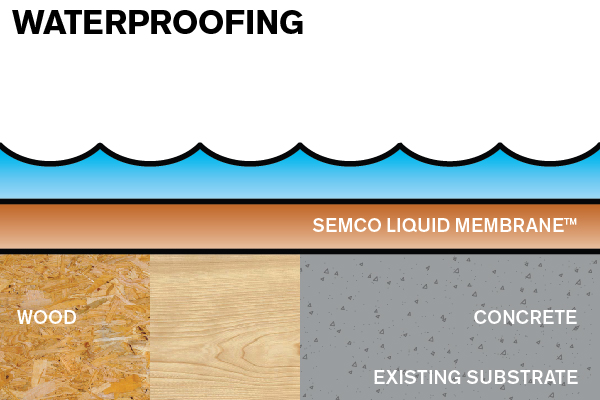

Waterproofing concrete and wood substrates

SEMCO Liquid Membrane™ is the perfect self adhering Membrane for waterproofing concrete and wood substrates. Use it for your shower, fountain, pool interior and protect it from long term water or moisture damage

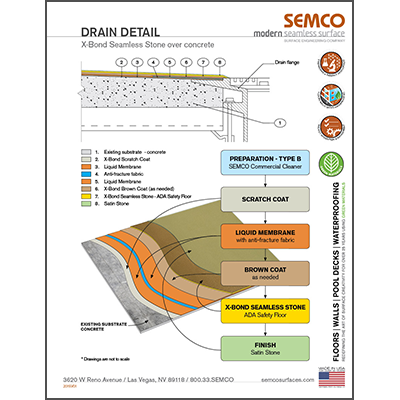

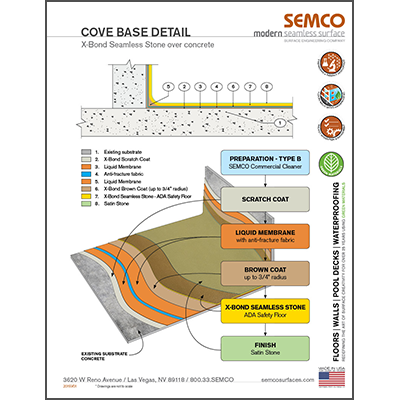

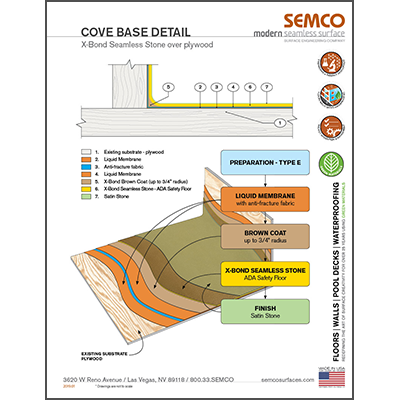

* Drawing is not to scale

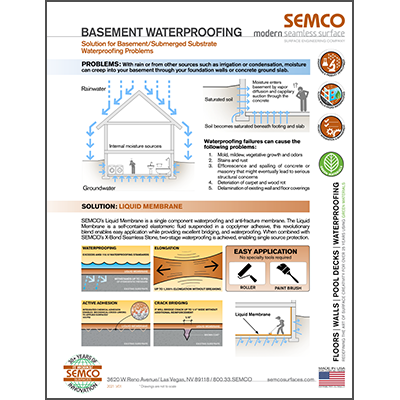

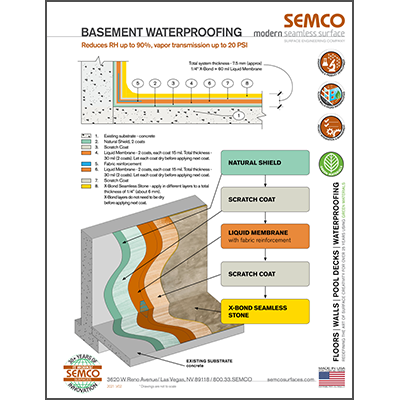

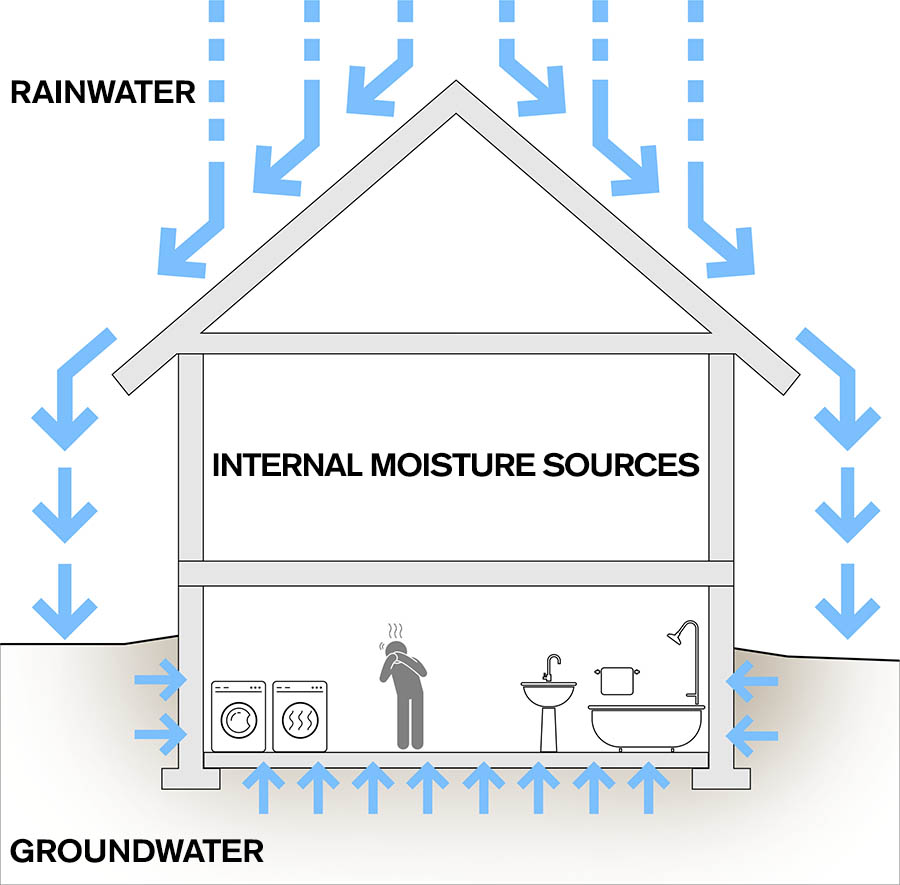

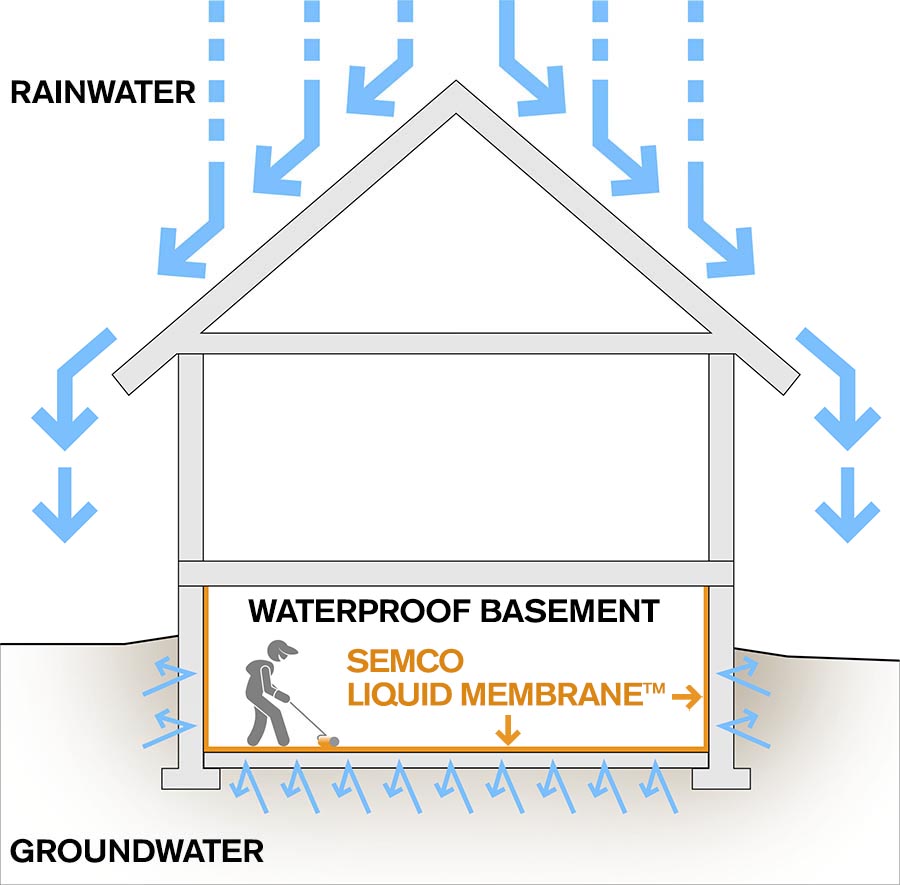

Basement waterproofing problems

Basement waterproofing problems: with rain or from other sources such as irrigation or condensation, moisture can creep into your basement through your foundation walls or concrete ground slab.

Waterproofing failures can cause the following problems:

- Mold, mildew, vegetative growth and odors

- Stains and rust

- Efflorescence and spalling of concrete or masonry that might eventually lead to serious structural concerns

- Deterioration of carpet and wood rot

- Delamination of existing wall and floor coverings

Solution – SEMCO’s Liquid Membrane™

SEMCO’s Liquid Membrane™ is a single component waterproofing and anti-fracture membrane. When combined with SEMCO’s X-Bond Seamless Stone, two-stage waterproofing is achieved, enabling single source protection.

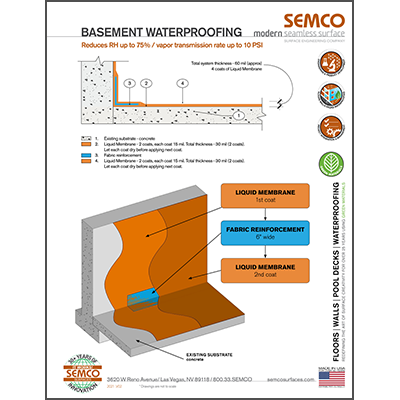

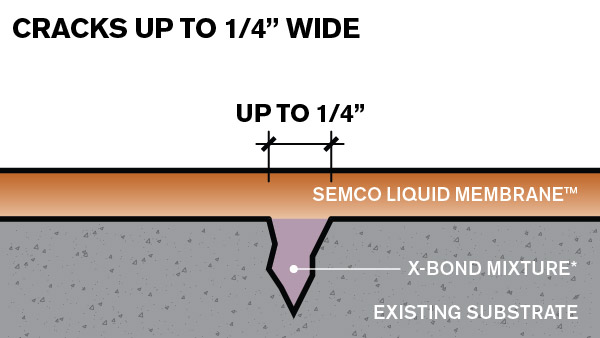

Repair cracks up to 1/4″ wide

Repair existing surface cracks and imperfections to ensure clean and smooth finish application.

* Drawing is not to scale

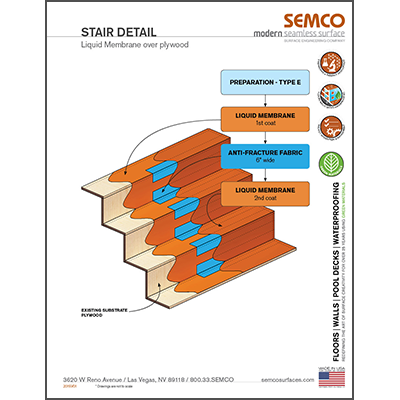

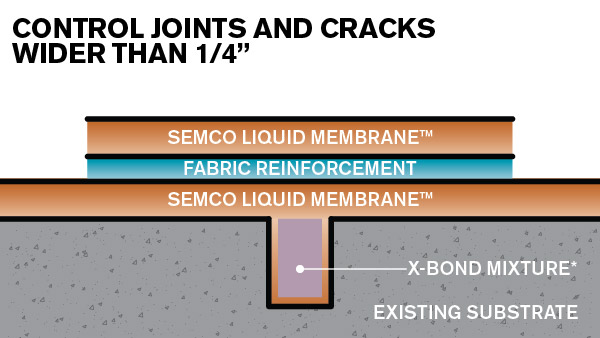

Repair control joints and cracks wider than 1/4″

Up to 400% stretch and elongation providing future crack suppression for years to come.

* Drawing is not to scale

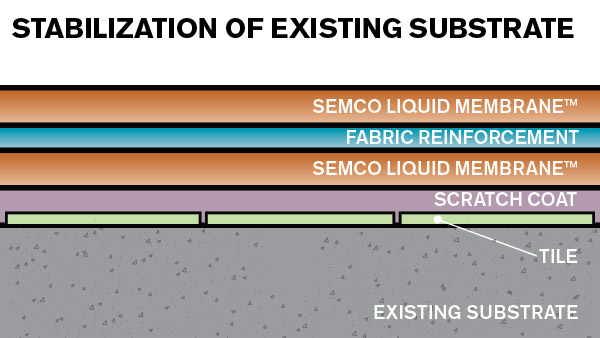

Stabilization of deteriorating and crumbling surfaces

Apply X-Bond Liquid and Scratch Coat to the deteriorating and crumbling surfaces in order to solidify it.

* Drawing is not to scale

SPECIFICATIONS

| Color | Orange (other colors available on request) |

| Chemical type | Latex – cross-link hybrid |

| Clean up | SEMCO Stone Soap with water |

| Shelf life | 2 year in controlled environment (ambient temperature of 60ºF – 72ºF) |

| Packaging | 1 gal | 5 gal | 55 gal |

| Warranty | 5 year standard limited warranty, 10 year for non-traffic surfaces |

DRYING / RECOAT TIME

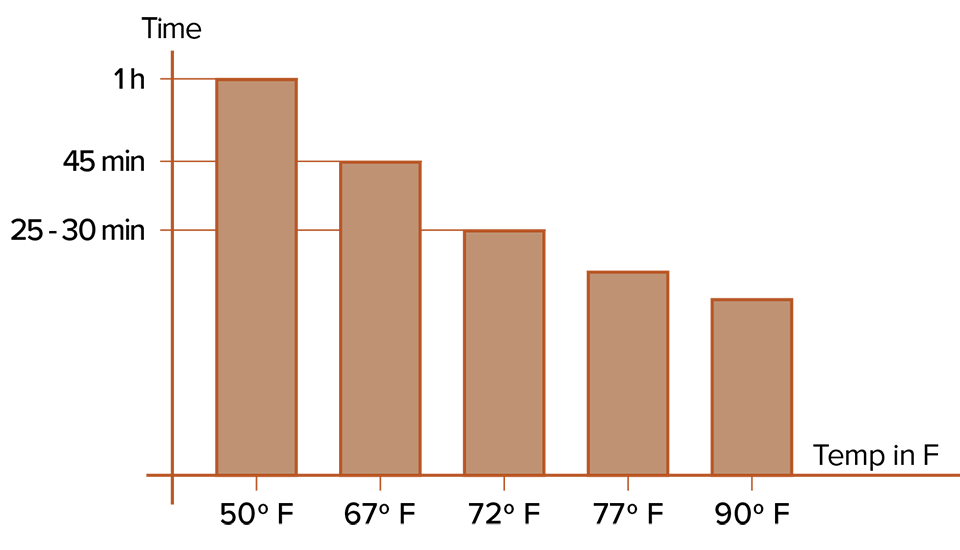

DRYING / RECOAT TIME

Drying times are affected by temperature and relative humidity. The chart represents guidline values but each project is to be treated individually.

The chart represents the time needed in between coats at specified temperature.

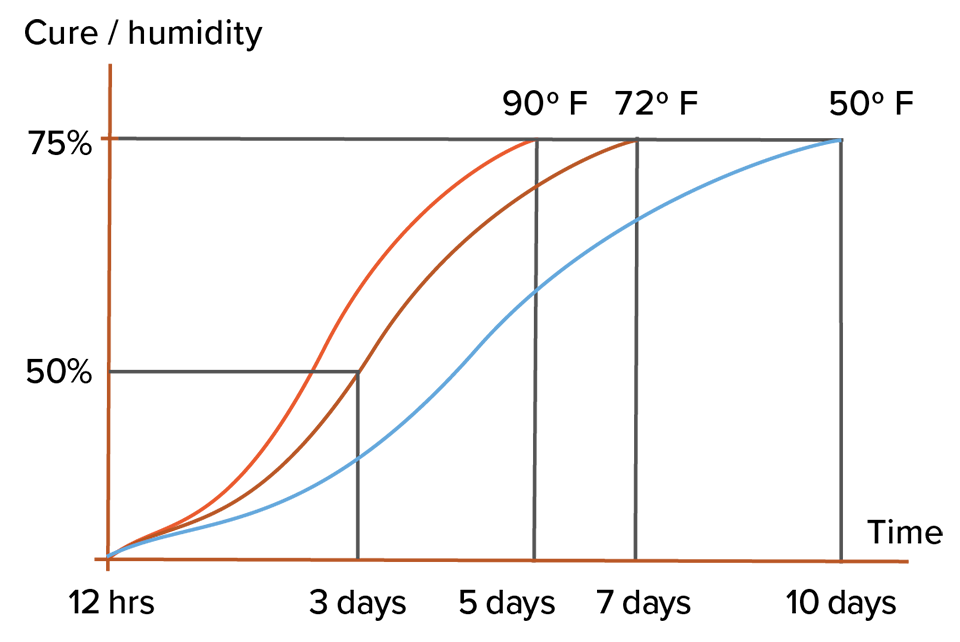

CURE TIME

Curing time is affected by temperature and humidity.

For example at only 50º F, a full cure would take 10 days in comparison to at 95º F it would only take 5 days to cure.

LABORATORY TEST RESULTS

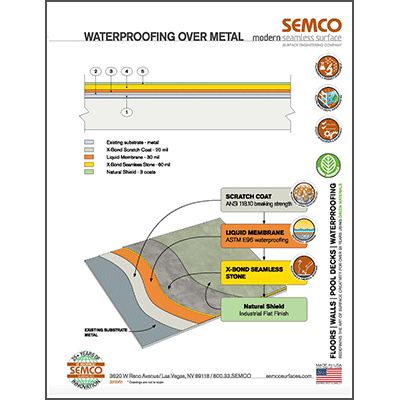

| ANSI 118.10 – Breaking Strength ( ASTM D751, Procedure B ) | Pass |

| ANSI 118.10 – Dimensional Stability ( ASTM D1204 ) | Pass |

| ANSI 118.10 – 7-Day Shear Strength ( ASTM C482-9.8) | 173 PSI / shear |

| ANSI 118.10 – 7-Day Water Immersion Shear Strength | 132 PSI |

| ANSI 118.10 – 4-Week Shear Strength | 234 PSI |

| ASTM E96 – Water Vapor Transmission | 1.52 (g/hr-m2) |

| ASTM E96 -Water Vapor Transmission : Permeability | 0.135 (perm-in) |

| ISO 37 – Tensile Strength ( ASTM D412 ) : Maximum Stress | 453 PSI |

| ISO 37 – Tensile Strength ( ASTM D412 ) : Ultimate Elongation | 321 % |

| ASTM D42370 – Tensile Strength: Maximum Stress | 184 PSI |

| ASTM D42370 – Tensile Strength: Ultimate Elongation. → WATCH VIDEO | 1,300% |

| AS 4858.1 Appendix A : Elongation at Break | 1375% |

| AS 4858.1 Appendix A : Stability of Membrane Water Immersion | 588% |

| AS 3558.1 : Water Absorption | 2.33% |

| AMTM004 : Temperature Resistance | 2.7g/m2/24h |

| VOC Content | 14 g/L |

APPLICATION INSTRUCTION

- STEP 1

HOW : Sweep debris off of surface and loose surface

PURPOSE : Ensure proper bond to substrate

- STEP 2

HOW :Use a 1/2″ nap roller. Allow any pre-treated areas to dry to the touch. Apply a generous coat of SEMCO Liquid Membrane™ with brush or roller over substrate including pre-treated areas. Apply another generous coat of SEMCO Liquid Membrane™ over the first coat of SEMCO Liquid Membrane™. Once you can walk on the surface and not get any residue on your shoe or feet or cannot leave a fingerprint impression it is ready to re-coat. Apply another thin coat of SEMCO Liquid Membrane™ in an alternate direction over the first coat of SEMCO Liquid Membrane™.

Let topcoat dry to the touch, approximately 1–2 hours at 70 °F (21 °C) and 50% RH. When last coat has dried to the touch, inspect final surface for pinholes, voids, thin spots or other defects. SEMCO Liquid Membrane™ will dry to bright orange color when it’s dry to touch. Use additional SEMCO Liquid Membrane™ to seal the defects. Required thickness is 30 mil

PURPOSE : Suitable of all sizes of installations, and ensures best performance of the SEMCO Liquid Membrane™

- SPRAYING APPLICATION

HOW : The sprayer being used for the application of SEMCO Liquid Membrane™ should be capable of producing a mini- mum of 2,500 psi (17.2), maximum of 3,300 psi (22.8 MPa) with a flow rate of 0.95 to 1.6 GPM (3.6 to 6.0 LPM) using a 0.521 or a 0.631 reversible tip. Keep the unit filled with SEMCO Liquid Membrane™ to ensure con- tinuous application of liquid. The hose length should not exceed 100’ (30 m) in length and 3/8” (9 mm) in diameter.

Required thickness is 30 mil

PURPOSE : Reserved for exceptionally large areas, and ensures best performance of the SEMCO Liquid Membrane™

- Precautions

- For clean up use warm water to clean brush or roller right after use.

- For optimal bonding we highly recommend preparing the surface as mentioned above for best results.

- Stir up the product well before use in order to mix up the color pigments.

- Avoid application in direct sun light in the afternoon or temperatures of over 85F as it might cause the product to dry too fast before it can adhere to the substrate

- Before applying next coat, ensure RH is max. 25% on the surface

- For applications where the product is fully submerged 3 coats @0.02 inch thickness per coat is required and allow a curing time of minimum 6-7 days. It is required to apply SEMCO Liquid Membrane™ in a continuous manner until above the water line. We do not recommend partial applications that are submerged.

- Coverage may vary depending on porosity of the substrate and also the thickness of coat being applied.

- For applications on fiberglass and metal, it is recommend to apply thinner coats (15mil thickness) in order for product to dry more evenly.

Scan QR Code to watch our application instruction step by step for a successful install or by clicking on this link !

FAQ – Frequently Asked Questions

The SEMCO Liquid Membrane™ is a single component waterproofing and anti-fracture membrane. It is a self-contained elastomeric fluid suspended in a copolymer adhesive, this revolutionary blend enables easy application while providing excellent bridging, and waterproofing. SEMCO Liquid Membrane™ creates a continuous waterproof membrane barrier with outstanding adhesion and reduces crack transmission in tile, concrete and stone floors.

- Easy to use – can be applied with a roller or brush

- Rated for heavy duty service

- Suitable for waterproofing pools, water features, showers and wood surfaces

- 400 % stretch and elongation. Stabilizes wood substrates to receive surface finish products

- 500 PSI or 3.44 N/mm2 adhesion

- Quick drying time allows you to proceed within 2 hrs of application with your finish

SEMCO Liquid Membrane™ is the perfect self adhering membrane for waterproofing concrete and wood substrates. Use it for your shower, fountain, pool interior and protect it from long term water or moisture damage.

- Concrete, cement mortar, masonry

- Cement Backerboard

- Exterior Plywood and OSB

- Exterior Decks

- Post-Tension Concrete

- Lightweight Concrete

- Gypsum-Based cement topping

- Existing tile and resilient flooring

Yes, SEMCO Liquid Membrane™ has undergone the following tests:

| ANSI 118.10 – Breaking Strength ( ASTM D751, Procedure B ) | Pass |

| ANSI 118.10 – Dimensional Stability ( ASTM D1204 ) | Pass |

| ANSI 118.10 – 7-Day Shear Strength ( ASTM C482-9.8) | 173 PSI / shear |

| ANSI 118.10 – 7-Day Water Immersion Shear Strength | 132 PSI |

| ANSI 118.10 – 4-Week Shear Strength | 234 PSI |

| ASTM E96 – Water Vapor Transmission | 1.52 (g/hr-m2) |

| ASTM E96 -Water Vapor Transmission : Permeability | 0.135 (perm-in) |

| ISO 37 – Tensile Strength ( ASTM D412 ) : Maximum Stress | 390 PSI |

| ISO 37 – Tensile Strength ( ASTM D412 ) : Ultimate Elongation | 400% |

For cracks up to 1/4” wide you must fill the crack first with X-Bond mixture before applying the SEMCO Liquid Membrane™ over it.

For cracks wider than 1/4” or control joints, apply SEMCO Liquid Membrane™ first into the crack or control joint, fill it up and then apply another coat of SEMCO Liquid Membrane™ followed by fabric reinforcement and put a second coat of SEMCO Liquid Membrane™ over the fabric for maximum adhesion.