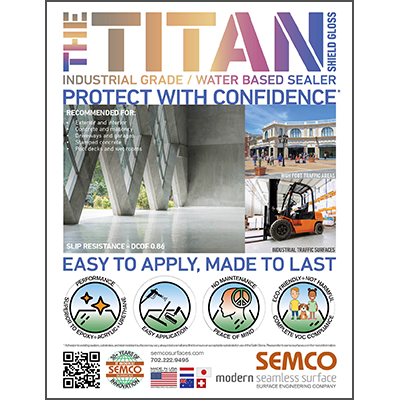

THE TITAN SHIELD GLOSS

EASY TO APPLY, MADE TO LAST

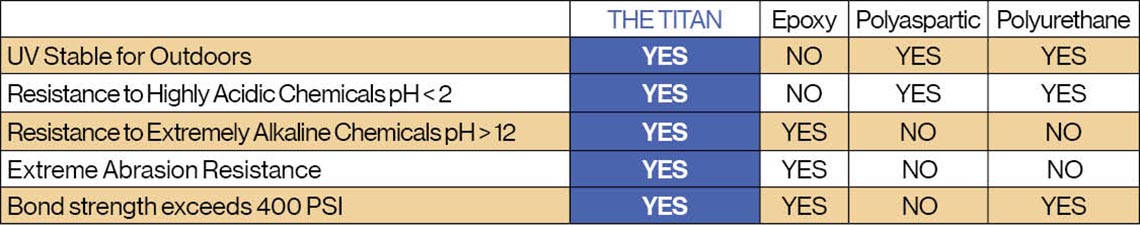

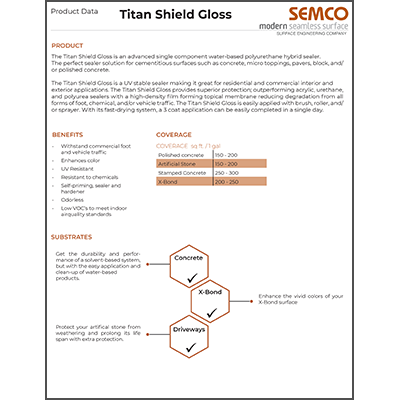

The Titan Shield Gloss is an advanced single component water-based polyurethane hybrid sealer. The perfect sealer solution for cementitious surfaces such as concrete, micro toppings, pavers, block, and/or polished concrete.

Withstands commercial and industrial vehicle traffic

Rejuvinates color and leaves natural look

Interior and exterior use

The Titan Shield Gloss is a UV stable sealer making it great for residential and commercial interior and exterior applications. The Titan Shield Gloss provides superior protection; outperforming acrylic, urethane, and polyurea sealers with a high-density film forming topical membrane reducing degradation from all forms of foot, chemical and vehicle traffic. The Titan Shield Gloss is easily applied with brush, roller or sprayer. With its fast-drying system, a 3 coat application can be easily completed in a single day!

SLIP RESISTANCE – DCOF 0.86

RECOMMENDED FOR

- Exterior and interior

- Concrete

- Masonry

- Driveways and garages

- Stamped concrete

- Pool decks

- Wet rooms

COVERAGE

sq ft / gallon, 3 coats @20 mils total thickness

| Polished concrete | 150 – 200 |

| Stamped concrete | 250 – 300 |

| X-Bond Stone | 200 – 250 |

| Artificial Stone | 150 – 200 |

| Masonry | 150 – 200 |

AVAILABLE IN COLOR and with a non-skid additive

APPLICATION

Airless sprayer

tip size 17, 600 PSI

3 coats minimum

Magic trowel

3 coats minimum

Roller

1/2″ nap, woven

3 coats minimum

Apply at temperatures from 50°F to 90°F.

Drying time: 20 minutes at 72°F.

Cure time : 48 hours at 72°F.

Application Instruction

STAGE 1 – REMOVAL OF DEBRIS

- HOW : Sweep debris off surface

PURPOSE : Ensures there is no debris in the sealer

- HOW : Use The Titan Shield Gloss (for interior and exterior surfaces)

PURPOSE : Creates natural gloss finish for commercial floors and walls, kitchens, medical and industrial spaces

STAGE 2 – SEALER MIXING AND APPLICATION

- HOW : Use airless sprayer with tip size 17 at 600 PSI. Position the airless sprayer gun at 18” away from the floor

PURPOSE : Smaller tip size and high pressure can cause a lot overspray. Allows product to lay down evenly on the surface

- HOW : OPTIONAL: use magic trowel to spread the product or roll product on with a 1/2″ nap roller. Do not go back and forth

PURPOSE : Allows product to lay down evenly on the surface

- HOW : Minimum of 3 coats is required to ensure 20 mils film thickness in total

PURPOSE : Ensures long lasting surface protection from industrial and commercial vehicle and foot traffic

SPECIFICATIONS

| Color | Milky white, dries clear |

| Chemical type | Polyurethane hybrid |

| Clean up | Water |

| Shelf life | 3 years in controlled environment (ambient temperature of 60ºF – 72ºF) |

| Packaging | 1 gal. pail | 5 gal. pail |

DRYING / RECOAT TIME

DRYING / RECOAT TIME

Drying times are affected by temperature and relative humidity. The chart represents guidline values but each project is to be treated individually.

The chart represents the time needed in between coats at specified temperature.

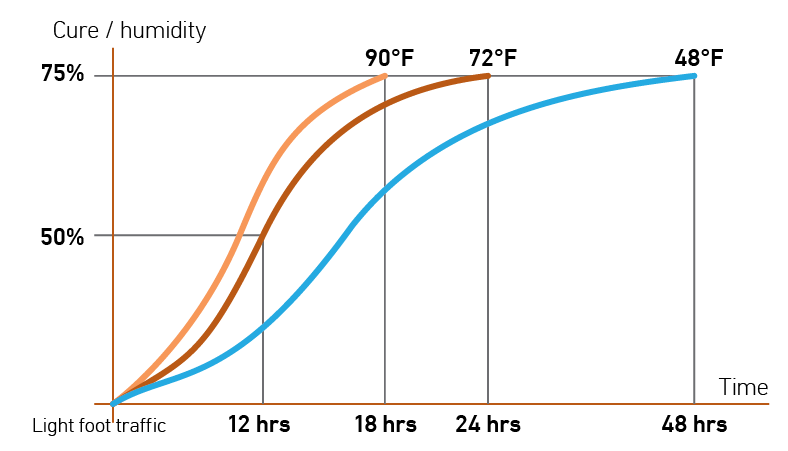

CURE TIME

Curing time is affected by temperature and relative humidity. The chart represents guideline values but each project is to be treated individually.

For example at only 48°F, a full cure would take 48 hours in comparison to at 95°F it would only take 18 hours to cure.

LABORATORY TEST RESULTS

| Used automobile oil | Excellent |

| Transmission fluid | Good |

| Cooking oil | Excellent |

| Alkali resistance | Excellent |

| Hydrolic acid (10%) | Good |

| Wine | Excellent |