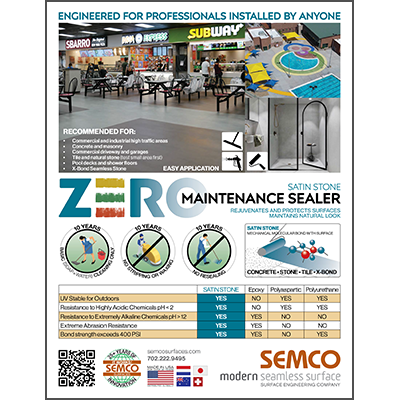

ZERO MAINTENANCE SEALER

ENGINEERED FOR PROFESSIONALS INSTALLED BY ANYONE

RECOMMENDED FOR

- Commercial and industrial high traffic areas

- Concrete and masonry

- Commercial driveway and garages

- Tile and natural stone (test small area first)

- Pool decks and shower floors

- X-Bond Seamless Stone

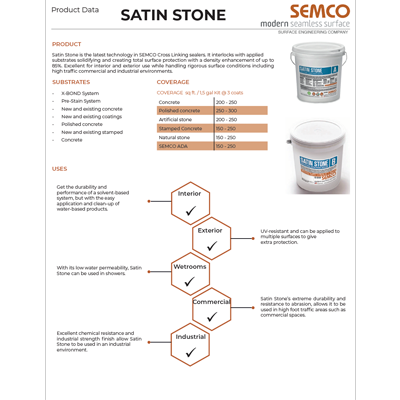

COVERAGE

sq ft / gallon, min 2 coats @ 20 mils total thickness

| Polished concrete | 200 – 250 |

| Stamped concrete | 300 – 350 |

| X-Bond Seamless Stone | 250 – 300 |

| Artificial Stone | 200 – 250 |

| LVT and VCT | 250 – 300 |

| Ceramic | 250 – 300 |

| Laminate | 250 – 300 |

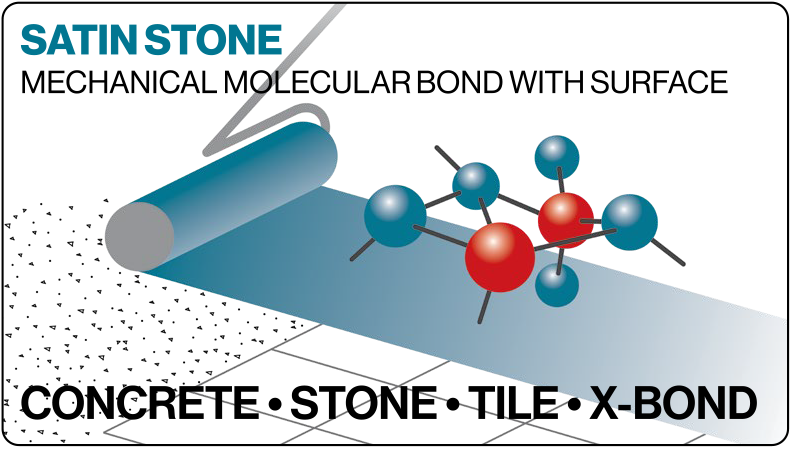

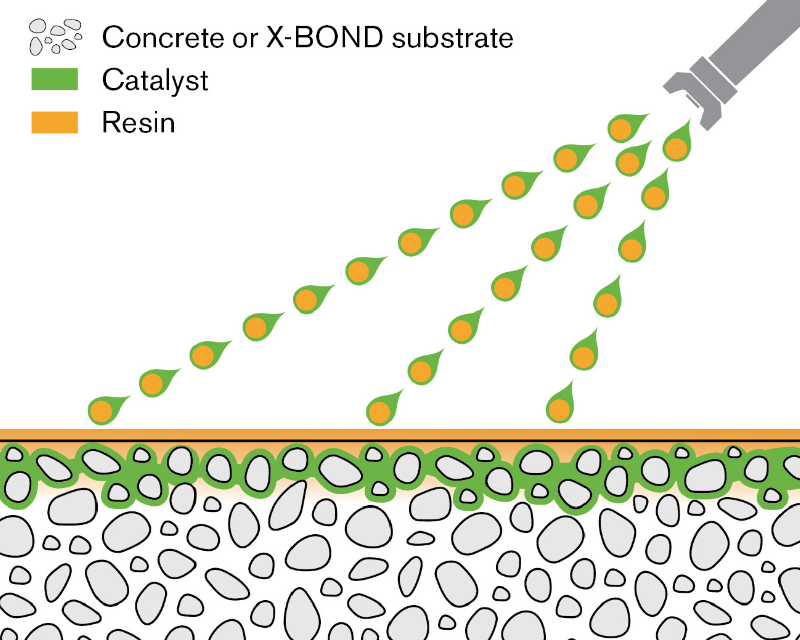

HOW SATIN STONE WORKS?

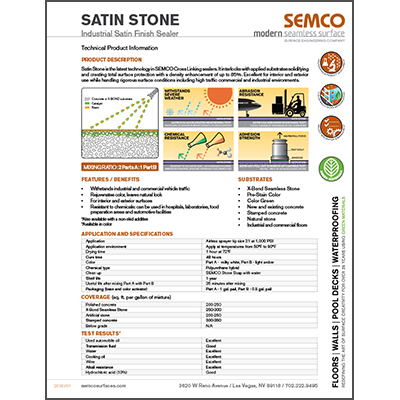

Satin Stone is the latest technology in SEMCO Cross Linking sealers. It interlocks with applied substrates solidifying and creating total surface protection with a density enhancement of up to 85%.

* Drawing is not to scale

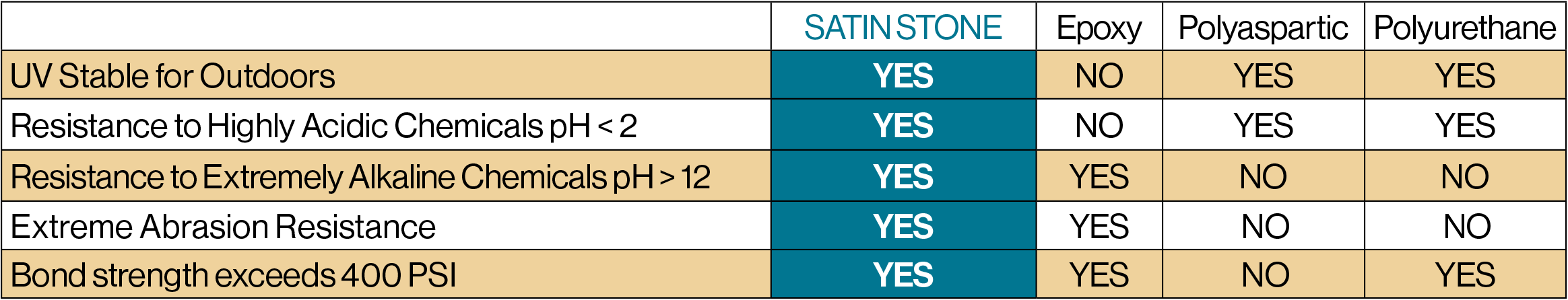

FEATURES AND BENEFITS OF SATIN STONE

Excellent for interior and exterior use while handling rigorous surface conditions including high traffic commercial and industrial environments.

ABRASION RESISTANCE

Withstands industrial and commercial vehicle traffic. ASTM 5155 Abrasion Resistance Test: 0.019% change in thickness after 10,000 rubs.

* Drawing is not to scale

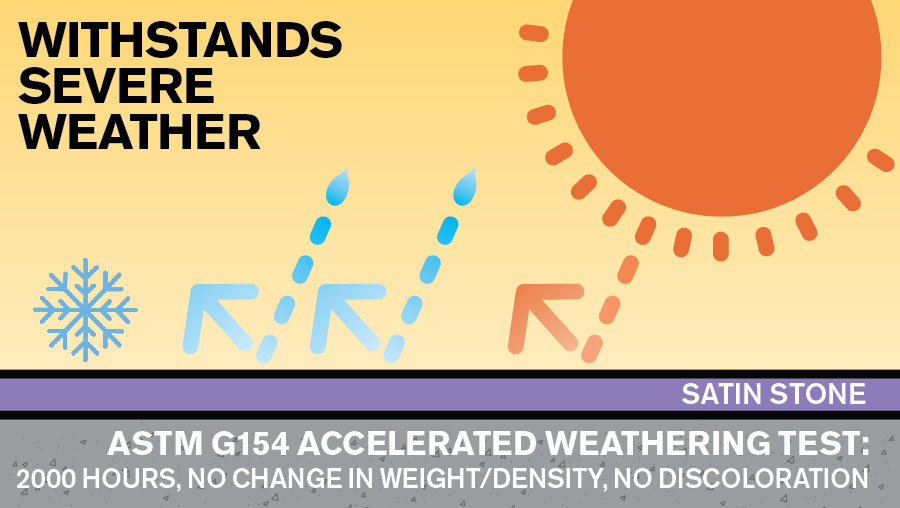

Withstands Severe Weather

Long lasting sealer for interior and exterior surfaces. ASTM G154 Accelerated Weathering Test: 2,000 hours, no change in weight/density, no discoloration.

* Drawing is not to scale

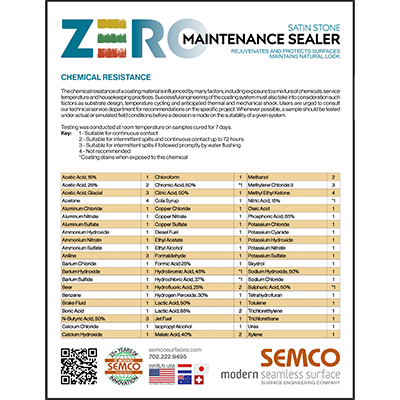

Chemical resistance

Resistant to chemicals: can be used in hospitals, laboratories, food preparation areas and automotive facilities. Resistant to 10% acetic acid , 10% hydrogen chloride, ammonium hydroxide, gasoline, hydraulic fluid, brake fluid.

* Drawing is not to scale

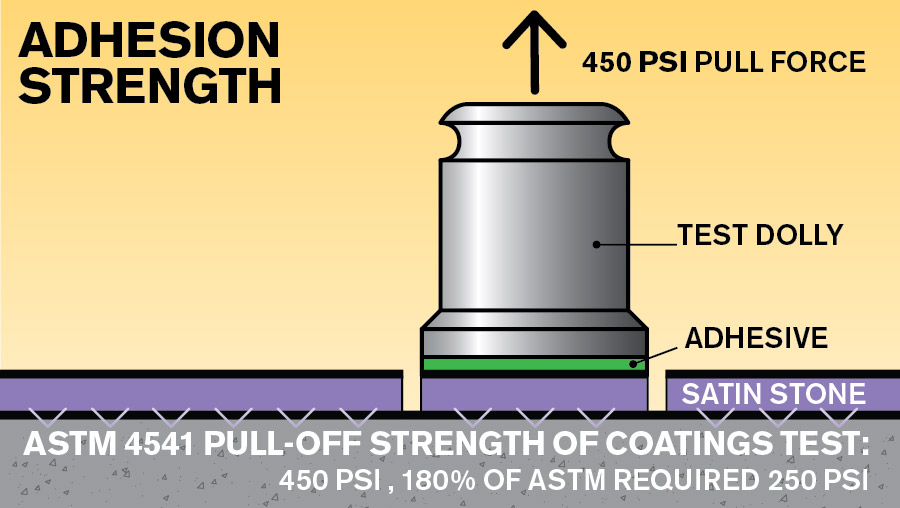

ADHESION STRENGTH

ASTM 4541 Pull-off Strength of Coatings Test: 450 PSI , 180% of ASTM required 250 PSI.

* Drawing is not to scale

AVAILABLE IN COLOR and with a non-skid additive

* Variations in color may occur depending on application, substrate condition and finishing sealer

APPLICATION

Airless sprayer

tip size 21, 1,000 PSI

Magic trowel

2 coats minimum

Roller

3/8″ soft woven roller

2 coats minimum

MIXING RATIO: 2 Parts A : 1 Part B

POT LIFE: 35 min

Apply at temperatures from 50°F to 90°F.

Drying time: 1 hour at 72°F.

Cure (50%) time : 72 hours at 72°F.

Application Instruction

STAGE 1 – REMOVAL OF DEBRIS

- HOW : Sweep debris off surface

PURPOSE : Ensures there is no debris in the sealer

- HOW : Use Satin Stone (for interior and exterior surfaces)

PURPOSE : Creates natural satin finish for commercial floors and walls, kitchens, medical and industrial spaces

STAGE 2 – SEALER MIXING AND APPLICATION

- HOW : Mix 2 parts of Part A and 1 part of Part B (included in your product order) with a low speed mixer and an epoxy mixing paddle (at only 200 – 300 RPM for 20 seconds) or by hand, stirring thoroughly, avoid mixing more product than can be applied. Product pot life is up to 35 minutes depending on temperature (MARK TIME ON CONTAINER)

PURPOSE : Low speed mixture, less air in mix reduces dry time to avoid wasted product. Since product is water-base will not get hard in container

- HOW : Use airless sprayer with tip size 21 at 850-1,000 PSI. Position the airless sprayer gun at 18” away from the floor

PURPOSE : Smaller tip size and high pressure can cause a lot overspray. Allows product to lay down evenly on the surface

- HOW : OPTIONAL: use magic trowel to spread the product or roll product on with a 3/8″ soft woven roller. Do not go back and forth

PURPOSE : Allows product to lay down evenly on the surface

- HOW : Minimum of 2 coats is required to ensure 20 mils film thickness in total

PURPOSE : Ensures long lasting surface protection from industrial and commercial vehicle and foot traffic

SPECIFICATIONS

| Color | Part A – milky white, Part B – light amber |

| Chemical type | Polyurethane hybrid |

| Clean up | SEMCO Stone Soap with water |

| Shelf life | 1 year in controlled environment (ambient temperature of 60ºF – 72ºF) |

| Useful life | 35 minutes after mixing Part A with Part B (ambient temperature of 60ºF – 72ºF) |

| Packaging | Part A – 1 gal. pail | Part B – 0.5 gal. pail |

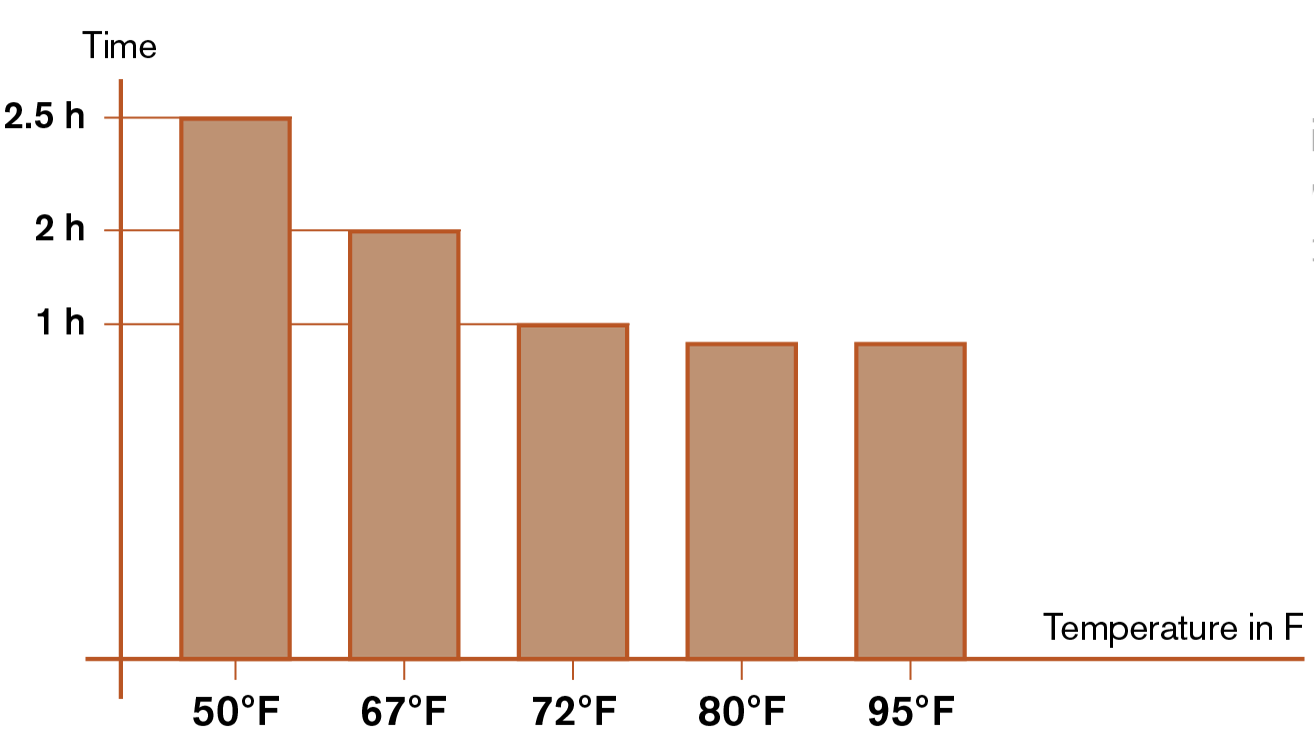

DRYING / RECOAT TIME

DRYING / RECOAT TIME

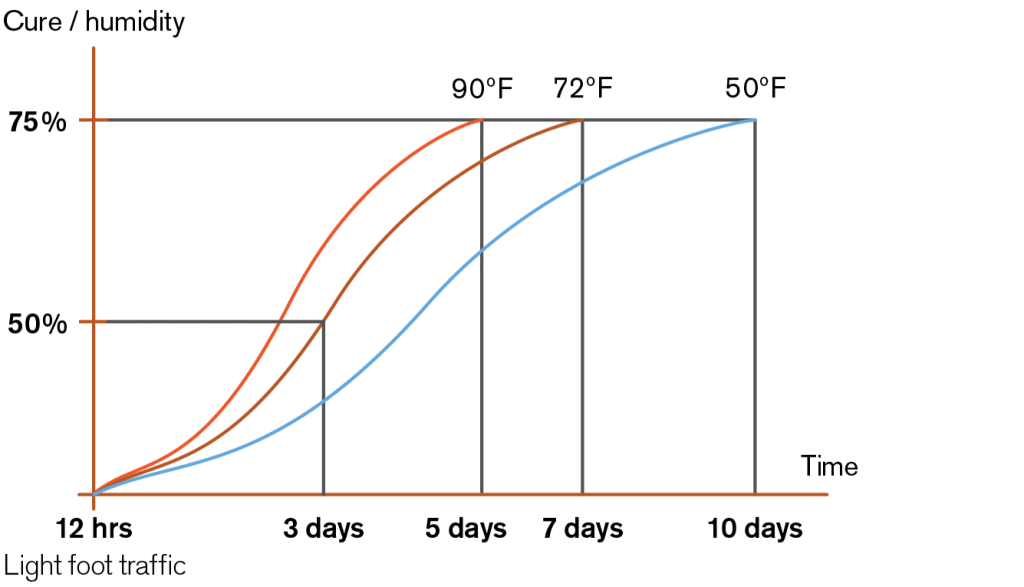

Drying times are affected by temperature and relative humidity. The chart represents guidline values but each project is to be treated individually.

The chart represents the time needed in between coats at specified temperature.

CURE TIME

Curing time is affected by temperature and relative humidity. The chart represents guidline values but each project is to be treated individually.

For example at only 50°F, a full cure would take 10 days in comparison to at 95°F it would only take 5 days to cure.

LABORATORY TEST RESULTS

| Used automobile oil | Excellent |

| Transmission fluid | Good |

| Cooking oil | Excellent |

| Alkali resistance | Excellent |

| Hydrolic acid (10%) | Good |

| Wine | Excellent |